A Case Study From FLIR

A wide variety of industries relies on furnaces and boilers for manufacturing processes. But furnace and boiler equipment is prone to failures from a variety of mechanisms. These include coking that plugs the inside of tubes and impedes product flow, slag build-up on the outside of tubes, clinker damage, under- and over-heating, flame impingement on tubes due to burner misalignment, and product leaks that ignite and cause serious damage to the equipment.

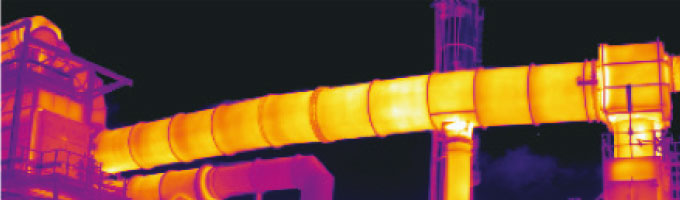

These failures cause not only quality problems; they can also shut down an entire process line. FLIR thermal imaging cameras can detect most of these equipment problems during operation, and at an early stage so failures can be prevented. This allows an orderly shutdown and component replacement, thereby reducing maintenance costs and production losses.

The French company Petroval was one of the first to recognize the potential of thermal imaging for technical inspections of industrial installations. “Before thermal imaging cameras were introduced there simply was no thorough way of finding failures during operation”, explains the project leader at Petroval. “Using FLIR thermal imaging cameras is a great non-destructive method to find such failures – even during operation – and accurately determine at what production speed it is still safe to operate.”

The Normandy, France, based company is owned by TOTAL and Eurecat and was founded in 1990. In addition to the head office in Le Havre, Petroval also has an office in Houston, Texas, since 2003, and will open an office in Singapore in 2011. Petroval provides services in more than 50 countries around the world; in fact more than 80% of the work is done outside of France.

Currently Petroval uses three thermal imaging cameras from FLIR; one with a cooled detector and two with an uncooled detector. The cooled thermal imaging camera is the FLIR Agema 550 with heat shield and flame filter. This camera is mainly used for inspections of the inside of the furnace. The two uncooled thermal imaging cameras are the FLIR ThermaCAM P50F, which also contains a flame filter, and the FLIR P640, which is mainly used for insulation inspection from the outside.

According to Petroval’s technicians all three cameras are great tools for his purpose. “The FLIR Agema 550 is very accurate and sensitive. The FLIR ThermaCAM P50F is not as sensitive to small temperature differences, but because it has an uncooled detector it is maintenance free and it takes less time to start up, for a cooled camera usually has to run the cooling system for about five minutes before it can be used. And the third one, the FLIR P640 is the perfect tool for both insulation inspection and for detecting faults in electrical equipment.”

The FLIR P640 thermal imaging camera has an uncooled microbolometer detector that produces thermal images of 640 x 480 pixels. The FLIR P640 has some very useful built-in features that make it ideal for predictive maintenance, such as a laser pointer, Picture in Picture and FLIR Thermal Fusion to merge the visual and the thermal image. “The FLIR P640 thermal imaging camera is very quick and easy to use. It’s great: even from a distance of fifty to a hundred meters you can still detect small hot spots that indicate insulation failure.”

The FLIR Agema 550 and the FLIR ThermaCAM P50F are both ‘older’ models that are not currently marketed by FLIR Systems. Today, the FLIR GF309 is the state of the art technology currently used for furnace inspections. In addition, this new model is a dual use thermal imaging camera that can not only be used for high temperature industrial furnace applications, but for thermal inspections of mechanical or electrical components as well. That makes these cameras ideal for monitoring all types of furnaces, heaters and boilers, particularly in the chemical, petrochemical and utility industries.

The FLIR Agema 550 contains a cooled Platinum Silicide (PtSi) focal plane array (FPA) detector. Platinum Silicide has been waived as a detector material because the PtSi detectors are less sensitive then indium antimonide (InSb) detectors, which form the heart of the new FLIR GF309 thermal imaging camera. This choice also allowed FLIR to market dual use thermal imaging cameras with better performances, because InSb detectors are more stable and more sensitive than PtSi or BB uncooled microbolometers.

The InSb detector in the FLIR GF309 thermal imaging camera produces images with a resolution of 320 x 240 pixels. Both the detector and filter are cooled with a small Stirling cycle cooler to near cryogenic temperatures to improve quantitative sensitivity. It has been built to withstand temperatures above 300°C, which allows temperature measurements up to 1500°C, and visual inspection of internal furnace and boiler components that would otherwise be obscured by flame, combustion gases, and dust. The camera produces real-time video images, but individual video frames can be captured as still images. The images can be viewed through a high-resolution viewfinder, and on a 4.3”, 800×480-pixel color LCD display. Custom-built to see through flames, the GF309 also features a detachable heat-shield designed to reflect heat away from the camera and camera operator, providing increased protection.

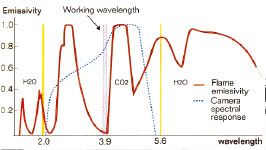

The FLIR GF309 thermal imaging camera has a flame filter, a spectral waveband filter that allows only thermal radiation with certain wavelength to pass through to the detector. Flames emit much more thermal radiation at certain wavelengths than at other wavelengths and at certain points in the spectrum a flame emits hardly any thermal radiation at all. A flame filter is a spectral waveband filter that only allows thermal radiation with those specific wavelengths through. The flame filter incorporated in the design of the FLIR GF309 restricts the spectral sensitivity to a range of 3.8μm – 4.05μm.

Because everything but that specific part of the spectrum is filtered out, the thermal imaging camera can now see through the flame and make temperature measurements straight through even exceptionally hot flames. This makes thermal imaging cameras equipped with such a filter ideal for furnace inspections.

Thermal imaging cameras from FLIR are a great tool for predictive maintenance in furnace and boiler installations, according to the spokesperson. “If you use thermal imaging cameras you know in advance what the weak points are. If certain tubes have flaws, for instance, you can buy the replacement tubes in advance and minimize the downtime.”

There’s a multitude of furnace faults you can detect with a thermal imaging camera, the spokesperson explains. “You can see whether the refractory is damaged, whether the flames have the right shape, and sometimes you can see dust deposits on tubes, which cause poor heat transfer and typically lower the temperature of the product. Refractory blocks can fall off, causing damage to burners and fired tubes. You can also see burners that are not lit, or burners causing flame impingement on the tubes. But we also look for oxidation development. Oxidation is a bad sign, for eventually the oxidation will peel off, leaving a weak spot. Temperature measurements with FLIR thermal imaging cameras help to make sure the entire process is working properly.”

“Temperature measurements also reveal coking that is taking place inside the tubes, usually due to excessive temperatures, and locations where there are tube restrictions or outright plugging”, said the spokesperson. “In some cases over-firing can cause temperatures that exceed the tube metal design criteria, and coupled with pressure inside a plugged tube may cause a rupture and leak. These will show up on the camera’s image display, along with actual temperatures of metal surfaces.”

According to Petroval’s technicians point temperature devices such as thermocouples provide too little information of what is actually going on inside the furnace. “Inspection ports provide a view of internal parts, but flames, combustion gases, and dust obscure fired tubes and burners when the equipment is operating. Temperature measuring devices like thermocouples can help discover some problems, but they only measure a single-point. Thermal imaging cameras from FLIR do more than measuring the temperature in one point. Temperatures can be read from every single pixel in the 320 x 240 or 640 x 480 pixels thermal image.

“Using the FLIR Reporter software we can analyse the recorded thermographic data to pick up the smallest thermal details”, continues the spokesperson.

One of the most important goals of furnace and boiler inspections is validating temperature readings from thermocouples, according to the spokesperson. “Thermocouple contact measurement devices or the welds that keep them in place can deteriorate over time and the measurement data becomes less accurate. In many cases refineries can operate at a much higher production capacity, but because of the inaccuracy of thermocouple readings the production is kept within a safe margin. Using our FLIR thermal imaging cameras we can find out if the temperature readings from the thermocouple are correct. When we have validated the thermocouple readings refineries are usually able to safely increase production.”

“Before we had thermal imaging cameras from FLIR there was no way to validate the temperature measurements of the thermocouples”, said the spokesperson. “We didn’t know if it was safe to improve the yield. Now we can very accurately say whether or not it is safe to do so. Many of the refineries we visit are producing at 30,000 tons a day, for instance, and due to our inspection they would find out that a production of 32,000 would also be safe.”

But anyone who thinks that performing furnace inspections is just a matter of point and click will be disappointed, according to the spokesperson. “However important having the right thermal imaging camera might be, there’s a lot more to it than that. The operators here at Petroval have many years of experience in performing thermal imaging inspections and analysing the data, but also with industrial furnace and boiler installations.”

“To name an example: we use special probes that we have made ourselves to make sure the thermal imaging camera is accurate. We insert the probe in the furnace and hold it next to the tube we want to look at. Inside the probe a thermocouple we know to be accurate tells us the exact temperature on that location. We then change the emissivity settings in order to make the temperature measured by the thermal imaging camera match the temperature measured in the probe. Because the emissivity is different for each material that is used we have made a probe for just about every type of tube that is used in industrial furnace installations.”

“But if you have the expertise and the right equipment then using these thermal imaging cameras from FLIR really is the best method for furnace inspection”, concludes the spokeperson from Petroval. “It’s a great non-contact, non-destructive way to gather both qualitative information and quantitative information that can help prevent or minimise downtime.”

Copyright © 2025 Butler & Land Technologies, LLC. All Rights Reserved.

Privacy Policy Return & Refund Policy Terms & Conditions Purchase Terms & Conditions