Photoelectric sensors use a variety of optical properties to detect objects, changes in surface conditions, and other items.

A Photoelectric Sensor is made up of two parts: an Emitter that emits light and a Receiver that receives it. The amount of light that arrives at the Receiver changes when emitted light is interrupted or reflected by the sensing object. This change is detected by the receiver, which converts it to an electrical output. Infrared or visible light (generally red or green/blue for identifying colors) is used by the majority of Photoelectric Sensors.

The light emitting element emits a beam of light, which is received by the light receiving element.

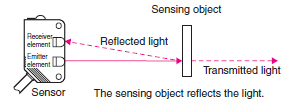

The light emitting and receiving elements are housed together in the same housing. The light from the emitting element passes through the reflector and is reflected back to the light receiving element. The light is interrupted when a target is present.

Retroreflective sensors can be used for a variety of applications, including:

A retro-reflective mode for clear object detection photoelectric sensor can be used to detect clear objects. To detect small changes in light that occur frequently when sensing clear objects, these sensors use a low hysteresis circuit. To reduce false responses caused by reflections from the target, the clear object mode sensor employs polarized filters on both the sensor transmitter and receiver.

When glossy targets are within a certain distance, or dead zone, retro-reflective sensors with foreground suppression will not mistake them for the reflector. Because a standard retro-reflective mode sensor can mistake the glossy covering for a reflector and not change state, this mode is ideal for detecting shrink-wrapped pallets. Optical apertures in front of the transmitter and receiver elements in the sensor housing create a zone that prevents reflective material from being detected incorrectly.

The light source and receiver are housed in the same device in optical proximity sensing, also known as diffuse. When a light beam emitted towards a target is reflected back to the sensor by the target, diffuse sensors detect it. Diffused sensors are a great automation option because they are more compact than traditional units because all of the components are contained in a single housing.

Sensors that are diffused can be used to:

Diffused sensors are the simplest to install because everything is contained in a single device, and they are also the most cost-effective sensing solution. Diffused sensors have the disadvantages of being less accurate in position detection than thru-beam and retroreflective sensors, as well as being less effective on translucent objects. Furthermore, color, texture, incident angle, target characteristics, and dirty environments can all have an impact on these sensors.

Convergent beam mode detects diffused modes more efficiently. In convergent beam mode, the transmitter and receiver lenses are focused on the same point in front of the sensor. The sensing range is fixed. The sensor can then detect an object within the “sensing window” plus or minus a distance. Front and back objects are ignored. The sensing window is affected by target reflectivity and sensitivity. The sensor can easily detect narrow or low reflectivity targets because all emitted energy is focused to a single point.

Target detection is limited by the “cut-off” distance of diffuse mode sensing with background suppression. Among the diffused mode variations, this one reduces color sensitivity. To ignore a background object that a standard diffused mode photoelectric sensor might misidentify as a target.

The diffuse mode can be used at a fixed or variable distance. Background suppression can be achieved mechanically or electronically.

The photoelectric sensor has two receiving elements, one for target light and the other for background light. The target is detected and the output is activated when the target receiver’s reflected light exceeds the background receiver’s. When the background receiver’s reflected light is greater than the target receiver’s, no target is detected and no output is changed. It can be adjusted mechanically for variable distance sensors.

For electronic background suppression, a Position Sensitive Device (PSD) replaces mechanical parts. One of the PSD’s two points where the target and background material reflect a light beam from the transmitter. The sensor compares the light striking these two points on the PSD to the pre-set value to determine whether the output changes state.

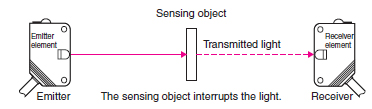

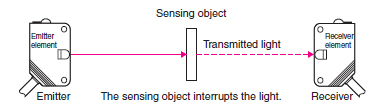

The transmitter and receiver are not in the same room. The light is interrupted when the target is between the transmitter and the receiver.

Two separate devices are used to make or break a beam in through-beam sensing, also known as opposed mode. The light emitter is housed in one sensor, while the receiver is housed in the other. When an object interrupts the light beam between two sensors, a through-beam sensor detects it.

Through-beam sensors can be used for a variety of applications, including:

The benefits of using a thru-beam sensor are that it is the most accurate and has the longest sensing range of the three types of sensors. When used in a dirty environment, through-beam sensors are the best option. It’s important to remember that this device will require the installation of at least two separate parts in order to function properly.

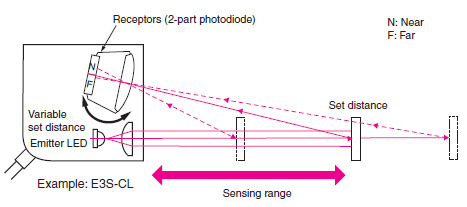

A two-part photodiode or a position detector is used as the sensor’s receiver. The light emitted by the sensing object is focused on the receiver. The principle of triangulation states that the concentration of the beam is proportional to the distance to the sensing object.

A two-part photodiode detection system is shown in the diagram below. The N (near) end of the photodiode is closest to the case, while the F (far) end is furthest away. When a sensing object reaches the preset position, the reflected light is concentrated halfway between the N and F ends, giving both photodiodes an equal amount of light. The reflected light is concentrated at the N end if the sensing object is closer to the Sensor. When the sensing object is located farther than the preset distance, the reflected light is concentrated at the F end. To determine the position of the sensing object, the Sensor calculates the difference between the light intensity at the N and F ends.

We at Butler & Land Technologies, specialize in photoelectric sensors. For product inquiries, please give us a call at (800) 527-6870 or Contact us.

Copyright © 2024 Butler & Land Technologies, LLC. All Rights Reserved.

Web Design by Red Spot Design. Return & Refund Policy, Terms & Conditions