Valves are mechanical devices that open, close, or partially obstruct the flow of water to control, direct, and regulate it. They can be made of a variety of materials, including bronze, PVC, brass, and other metals.

Valves are used to direct the flow, shut off water access, prevent backflow, and adjust water pressure in residential and commercial buildings, water supply systems, wastewater treatment plants, and chemical plants.

A valve is a component of a piping system that regulates the flow of media through the system. Manipulation of an obstructer within the valve is used to achieve this control. Actuated valves are powered by compressed air or electricity and use mechanical devices called “actuators” to operate the valve. Most actuated valves are also available in a manually operated or actuated with a manual override version.

The most common types of automated valves can be divided into three groups. They are self-actuated, linear, and rotary. Within each of these categories, there are a variety of valve types, each with its own set of advantages. The rotary and linear actuated valves are the focus of this training course.

These types of valves rely on the rotary motion of the flow obstructer In most cases this rotation is limited to 90 degrees (one quarter-turn), however, there are valves that operate using a larger degree of rotation and have more than 2 positions that are used in regular operation. Quarter-turn valves are completely closed at 0 and completely open at 90 degrees. Ball valves, plug valves, and butterfly valves are examples of quarter-turn valves.

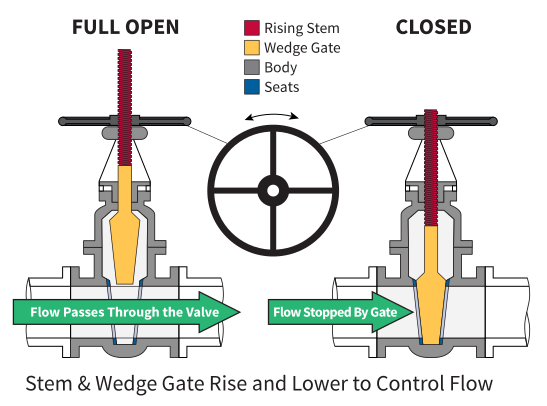

Rising stem (multi-turn) and axial linear valves are the two types of linear valves. While both valve types rely on the linear motion of the flow obstructer, their construction and operation are vastly different.

The obstructer is moved by the rotation of a threaded rod (stem) attached to the obstructer in multi-turn rising stem valves. Gate valves, globe valves, pinch valves, diaphragm valves, and needle valves are examples of multi-turn valves. These types of valves are frequently used in flow control applications.

Axial valves slide the obstructer along an axis using pneumatic or electro-magnetic force. Coaxial valves and angle seat valves are two examples of these. These valves are usually fast acting and only used in on/off processes.

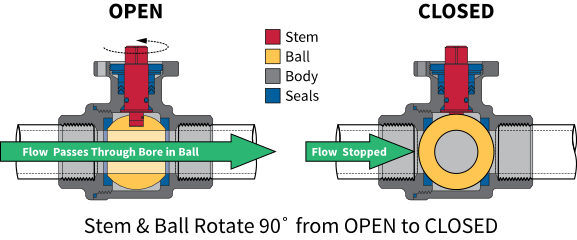

Ball valves have excellent shut-off properties. A quarter-turn (90°) opens or closes the valve completely. This feature cuts down on valve operation time and reduces the risk of leakage caused by gland seal wear.

Reduced bore and full bore ball valves are the two types of ball valves. The valve opening in reduced bore valves is smaller than the piping diameter; in full bore valves, the valve opening is the same size as the piping diameter. Ball valves with a full bore are popular because they reduce pressure drop across the valve.

Ball valves are typically only used in one of two positions: fully open or fully closed. Because ball valves have a ring-shaped soft valve seat, they are not suitable for regulating flow by being kept partially open. The pressure is applied to only a portion of the valve seat when it is partially open, which can cause it to deform. When the valve seat deforms, its sealing properties are compromised, and the valve leaks.

A ball valve is the least expensive of all valve configurations and requires little maintenance. Ball valves are compact, require no lubrication, and provide tight sealing with low torque, in addition to quick quarter-turn on-off operation.

The throttling characteristics of traditional ball valves are poor. The partially exposed seat erodes quickly in a throttling position due to the impingement of high-velocity flow.

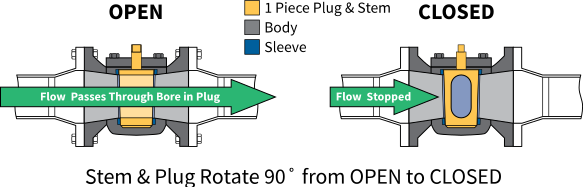

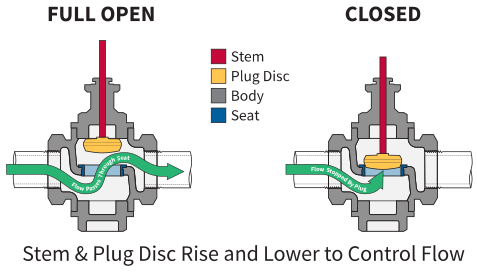

A plug valve is a rotational motion valve that controls fluid flow by stopping or starting it. The name comes from the disk’s shape, which resembles a plug. The petcock is the most basic type of plug valve. A plug valve’s body is machined to accept a tapered or cylindrical plug. The disk is a solid plug with a bored passage that runs perpendicular to the plug’s longitudinal axis.

The passage in the plug lines up with the inlet and outlet ports of the valve body in the open position. The solid part of the plug blocks the aperture and stops the fluid flow when it is turned 90 degrees from the open position. Plug valves are available in either a lubricated or non-lubricated design and with a variety of styles of port openings through the plug, as well as a number of plug designs.

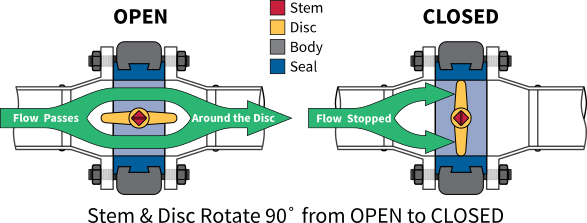

The flow is regulated in butterfly valves by a disc-type element held in place in the center of the valve by a rod. Valve operation time is similar to that of ball valves because the valving element is rotated a quarter turn (90°) to open or close the passageway.

Butterfly valves are distinguished by their straightforward design, light weight, and compact size. Because of their small face-to-face dimensions, butterfly valves have a much smaller pressure drop than globe valves (see below). At higher temperatures or with certain types of fluids, the materials used for the valving element and sealing can limit their applications. Butterfly valves are frequently used in water and air applications, as well as in large pipe diameter applications.

The gate valve is the most common type of valve found in industrial piping. The gate valve has a significant advantage in terms of flow obstruction, turbulence within the valve, and pressure drop. When the valve is fully open, the wedge is completely removed from the waterway, allowing for a straight flow path through the valve. When a pressure drop is to be avoided, the gate valve should be specified. Also, gate valves should only be used in the fully open or closed positions, not for throttling. If the wedge is left in an intermediate or partially open position, the bottom of the wedge and the seat will quickly erode. In addition, the wedge will chatter and make noise in the line.

When closed, a gate valve can be used for a wide range of fluids and provides a tight seal. The following are the major drawbacks of using a gate valve:

Globe valves work by raising and lowering a convex disc-shaped plug into a circular seat around the inside of the globe-shaped body at the “equator” via a rising stem. The flow enters the “lower hemisphere” from one side, travels up through the seat, and exits the “northern hemisphere” through the outlet on the opposite side. Globe valves can be used for both on/off and throttling purposes. 2-way globe valves are preferred for precise flow control, while 3-way globe valves are frequently used to mix media from two inlet ports and direct the mixture through an outlet port.

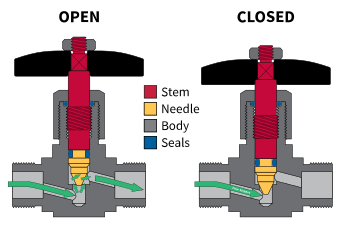

A needle valve is used to adjust the amount of fluid flow in a relatively fine manner. The long, tapered, needle-like point on the end of the valve stem is what distinguishes a needle valve. As a disk, this “needle” is used. The needle’s longer portion is smaller than the orifice in the valve seat and passes through it before the needle seats. This arrangement allows for a gradual increase or decrease in the opening size. Needle valves are frequently used as components of larger, more complex valves. They’re used in some types of reducing valves, for example.

To reduce the effects of fluctuations in pump discharge pressure, most constant pressure pump governors have needle valves. Needle valves are also used in some components of automatic combustion control systems that require extremely precise flow regulation.

A linear sliding obstructer opens and closes the valve, or changes the flow from one outlet to another, in solenoid valves. Obstructers come in a variety of shapes and sizes, including plunger, shuttle, spool, and diaphragm.

An electromagnetic coil is energized to pull the obstructer in one direction, resulting in linear motion. When the coil is de-energized, a spring forces the obstructer back in the opposite direction. The most common type of solenoid valve is a two-position on/off valve, but there are many others, including three-position valves, which have two coils that pull the obstructer in opposite directions and use springs to center it when neither is energized.

Flow control can even be accomplished with proportional solenoid valves. The coil in these valves moves the obstructer a variable distance depending on the voltage applied to it.

Solenoid valves are small valves. The strength of the coil, which is a result of the windings used to create a magnetic field when energized, limits their size. Aside from the coil’s strength limit, the flow paths and orifices in solenoid valves are quite small in comparison to the line size. This reduces flow while also increasing the pressure drop across the valve.

Dishwasher water lines and ice makers are two examples of common everyday applications. Solenoid valves are also used to control the supply air to pneumatic actuators in industrial valve automation.

Solenoid valves are not suitable if a high flow rate or a small pressure drop is required. Seat valves that are coaxial or angle are required.

The majority of solenoid valves have a valve body to which different coil types can be attached. The coils are available in a variety of voltages, connectors, and electrical protection ratings.

Coaxial valves are two-position valves that can be operated by pneumatic or electrical means. Electric versions, like solenoid valves, use an electromagnetic coil instead of a spring. Air pressure vs. a spring (spring return) or air pressure in both directions are used in pneumatic versions (double acting).

When a coaxial valve is open, the media passes through a shuttle-type obstructer. To perform its function, this shuttle moves to one of two positions: on/off or diverting flow to the proper outlet. When compared to solenoid valves, coaxial valves have a much larger flow path, but they still don’t come close to a full port valve. As a result, there is a flow restriction and an increase in pressure drop.

Coaxial valves would be a good substitute for a ball valve in many on/off applications. Coaxial valves have a smaller size and operate faster, whereas ball valves have higher flow rates and lower pressure drops.

Angle seat valves have a built-in pneumatic actuator and are 2-position valves. Spring return or double acting actuators are available. The obstructer is a plug that enters the valve at an angle and rests in an angled seat molded into the flow path of the valve. When the plug is open, it retracts almost completely out of the flow path. Angle seat valves are the highest flow fast-acting valves with the lowest pressure drop due to this factor. Angle seat valves are a great alternative to ball valves in many on/off applications. They are more effective, less expensive, and last longer.

Angle valves are ideal for low-pressure steam applications of less than 150 PSI.

Copyright © 2025 Butler & Land Technologies, LLC. All Rights Reserved.

Web Design by Red Spot Design. Return & Refund Policy, Terms & Conditions