A Guide for Investing in Infrared Cameras

Buying an infrared camera is a big commitment. Even though prices have fallen dramatically over the past few years, you want to ensure that you’re getting the best value for your money and choosing the camera that will serve you well over the long term. For some, the cost will be the driving force, while essential hardware or software features are more important for others. Whichever camera you choose should offer quality and dependability, along with excellent technical support and service.

There are many choices in thermal imagers, ranging from highly affordable point-and-shoot models to highly specialized HD-level science and research cameras. Finding the right fit for your needs can seem daunting. So along with the twelve things in this booklet to consider, you’ll find it helpful to define what you’re going to use the camera for and the work environments where you’ll be performing inspections. Do your research on where thermal imaging technology is headed and the potential career and business opportunities on the horizon. In other words, think beyond your current needs to ensure you’ve done your best to future-proof your IR camera investment.

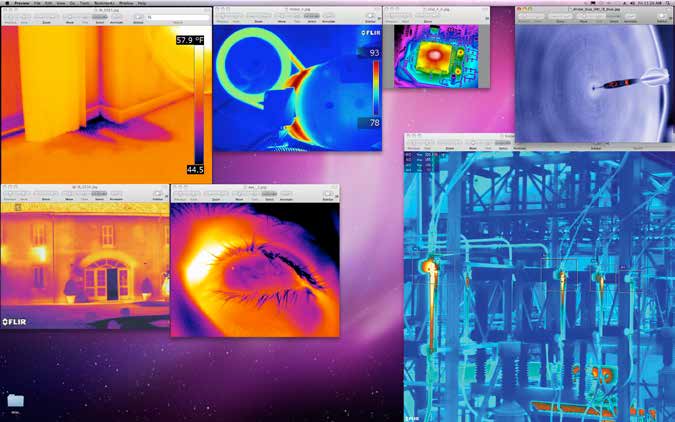

If your specialty is weatherization, maybe all you need is a simple, lower-cost point-and-shoot IR camera to spot missing insulation, poor weather stripping, and leaking windows. If you’re an energy auditor, you may want a more advanced model that helps you generate professional, customized reports or one that allows you to send images via a Wi-Fi mobile device to an agency that subsidizes improvements. Perhaps you need the benefit of higher resolution thermal imagery to help you build a strong marketing campaign for your services. Or you’re a restoration or HVAC contractor who needs a camera that links to moisture meter data to quantify the extent of damage better or to track down condensation problems and coolant leaks. Predictive maintenance professionals also have various needs that determine the kind of IR camera they should consider. A utility troubleman may only require a simple point-and-shoot camera to do a safety check of energized equipment before performing repairs or doing a quick connections inspection. Another member on his crew might need a high-resolution thermal imager to scan substations and power lines from a safe distance and gather detailed and accurate temperature measurements. Facility maintenance personnel and electricians might benefit from a camera that provides flexible ergonomics, allowing them to comfortably point the imager around tight corners, down behind motors, or straight up for equipment inspections overhead.

As you can see, there are a variety of applications, features, and other factors to consider. With the help of the “12 Things” included in the following pages and your list of needs, you’ll be able to make a more informed IR camera buying decision. Of course, we at FLIR are always available to answer any questions and help guide you through the process.

We want you to succeed, and we back up that commitment with nearly 50 years of infrared camera experience — an important consideration. As the world’s leading infrared camera manufacturer and with ITC, the world’s largest infrared training organization, we know a thing or two about thermal imaging, which is why you can trust this publication to help you by making the right choice.

If you have a question on what is presented here or want to explore more details about which infrared camera is best for you, please send us an email; sales2014@butlerandland.com Please note that the term “infrared camera” is used interchangeably with “thermal imager.”

Most infrared cameras have fewer pixels than visible-light cameras, so pay close attention to detector resolution. Higher resolution infrared cameras can measure smaller targets from farther away and create sharper thermal images, both of which add up to more precise and reliable measurements. Be aware of the difference between detector and display resolution. Some manufacturers will boast about a high-resolution LCD and] hide their low-resolution detector when it’s the detector resolution that matters most.

For instance, a 640 × 480 resolution LCD screen may be capable of displaying 307,200 pixels of image resolution. But if the IR detector only offers 19,200 resolution (160 × 120 pixels), the display resolution accomplishes little. The quality of the thermal image and its measurement data are always determined by the detector resolution, not the screen resolution.

Higher-resolution thermal imaging not only provides more accurate quantitative results, it is also very effective in showing finer detail findings to customers, supervisors, repair crews, and insurance companies that help shorten the decision-making process. Superior IR image quality is also valuable for generating more precise reports and for marketing your services.

There’s no need to carry a separate piece of equipment to take photos when many affordable IR cameras now include a built-in digital camera that simultaneously captures visible light and thermal images. Digital images that correspond to your IR images will help you further document a problem and communicate its precise location to decision-makers. If your customer or supervisor needs to see a comprehensive report, you’ll want a thermal imaging camera with this feature. And be sure it includes an onboard lamp that doubles as a flashlight to illuminate darker areas.

Built-in laser pointers are also invaluable, especially for isolating the location of a target surrounded by similar-looking components, such as breakers, or for pinpointing problematic energized electrical equipment where you need to keep your distance. Laser markers show up clearly on visible light pictures to provide a reliable reference. They’re also indicated on IR images as well as the thermal camera’s display, so you’ll be confident you’ve captured all the necessary information.

Infrared cameras don’t just let you see differences in heat; they measure those differences. Therefore, measurement accuracy and consistency are critical factors when determining the value of a camera.

For best results, look for a thermal imager that meets or exceeds ± 2% (or 3.6°F) accuracy. All FLIR cameras maintain that minimum standard, made possible by the company’s ability to manufacture its thermal imaging detectors.

But that’s not the only criteria. To produce correct and repeatable results, your thermal imager should include in-camera tools for entering both “emissivity” and “reflected temperature” values.

An infrared camera that gives you an easy way to input and adjust both of those parameters will produce the accurate temperature measurements you need in the field to make the best decision.

Other helpful diagnostics to consider are multiple moveable spots and area boxes for isolating and annotating temperature measurements that can be saved as radiometric data and incorporated into findings for reports.

As you become more experienced with your infrared camera, these features will become more meaningful. But before you proceed with your buying decision, find out whether the thermal imager you like offers these capabilities.

Many infrared cameras store images in a proprietary format that specialized software can only read and analyze. Others have an optional JPEG storage capability that lacks temperature information. On the other hand, FLIR has the distinction of offering a standard JPEG with full temperature analysis embedded. This allows you to e-mail your customers or colleagues IR images without losing that vital information. Radiometric JPEGs can also be imported from Wi-Fi compatible cameras to select mobile devices using apps that further image editing, analysis, and sharing. After all, it would help if you didn’t have to waste time converting images. Instead, request a demo from the infrared camera manufacturer and have them show you how the camera you’re considering will output JPEGs without a bunch of extra steps.

Also, look for infrared cameras that allow you to stream MPEG 4 video via USB to computers and monitors. This is especially useful for capturing dynamic thermal activity where heating and cooling occurs rapidly and recording motorized equipment or processes in motion. Some cameras feature composite video for cabling to digital recorders, while others include HDMI outputs. Mobile applications have also been developed that allow streaming video over Wi-Fi. All these capabilities will help you share findings more effectively and enhance your infrared inspections and reports.

Test and measurement tools like FLIR MeterLink products allow certain thermal cameras to measure more than temperature to fully quantify the severity of moisture damage and electrical issues. These moisture and clamp meters wirelessly transmit vital diagnostic data such as humidity, amperage, voltage, and resistance directly to the camera. The data is annotated automatically to the thermal image and embedded in the radiometric JPEG to add support to findings. This provides extremely valuable information to help you determine the urgency of a problem and decide on the best solution.

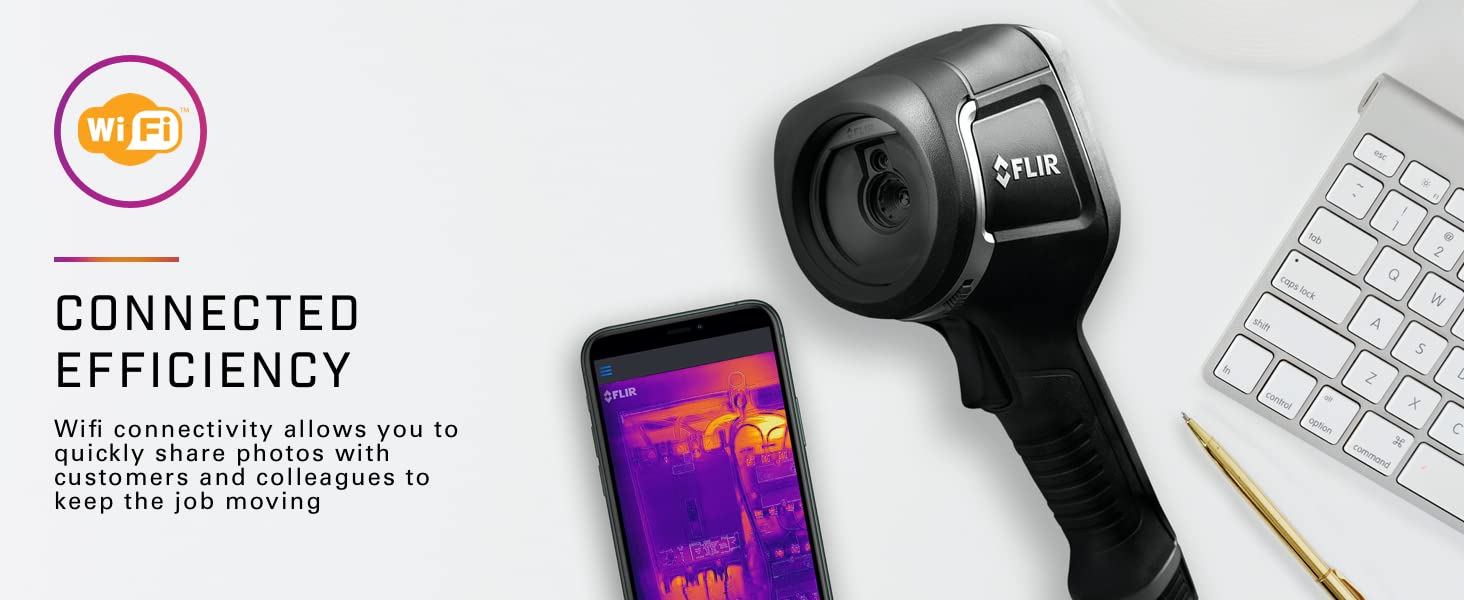

Many models of FLIR cameras, including the Exx-Series and T-Series, are Wi-Fi enabled for instant connection to smartphones and tablets running the FLIR Tools® Mobile app. This application allows user to import IR images to the mobile device for portable analysis, report generation, and sharing. The advantage of being able to send thermal images and IR inspection reports wirelessly from one part of a facility to another or by email from the field is huge when time is of the essence. The app malso allows live streaming video for customers and co-workers to view inspections from a safe, convenient distance. FLIR Tools Mobile also lets users take remote control of many major T-Series camera functions like focus, image level and span adjustments, adding temperature measurement tools. This comes in handy when it’s necessary to set the camera up on a tripod for monitoring equipment over time, for example.

Electrical contractors and thermographers can also take advantage of the FLIR InSite workflow management tool. The mobile and desktop application work together to streamline the thermal inspection process, simplify data collection, and speed up reporting. By following the application’s easy Prepare – Inspect – Deliver workflow, you can set up efficient survey route and then run them from the mobile app during your inspection. While in the field, you can maintain accurate documentation by assigning thermal images and survey data directly to saved assets. Once you’re finished with the survey, you can deliver inspection results through a secure and private client portal on the FLIR InSite cloud.

Copyright © 2025 Butler & Land Technologies, LLC. All Rights Reserved.

Web Design by Red Spot Design. Return & Refund Policy, Terms & Conditions