It is impossible to imagine modern society existing without electricity. If we are disconnected from the grid for a long time, it might end up costing more than just money. Since hospitals and other emergency services rely on electricity, a prolonged power outage could result in fatalities. To improve security at key points in the electricity network, the Norwegian government and energy providers like Lyse Energy have begun installing thermal imaging cameras.

The Lyse Energy electrical substation in Stavanger, Norway, is one of the places where thermal imaging cameras were installed to improve perimeter protection. Noralarm AS is the business that put in the thermal cameras. The staffing of the control room is also the responsibility of this Norwegian security firm. According to Torje Knag, CEO of Noralarm AS, “We looked into a variety of security solutions, but thermal imaging is the only one that works.”

One of Norway’s top alarm and security providers, NorAlarm is the only business in the area with a police- and insurance-approved (FG) alarm monitoring center that is open twenty-four hours a day, every day of the year. The company, which was founded in 1998, specializes in the provision of operational services, as well as the sales, design, installation, and maintenance of cutting-edge security solutions connected to a specialized alarm center for the professional and private market.

It is crucial to maintain power distribution while maintaining the security of the electrical substation to guard against vandalism and terrorist attacks. But Knag also points out that there are other dangers. Wear-related breakdown can be extremely expensive as well as dangerous. We made the decision to integrate online thermographic monitoring into the security system for this reason. We ensure that faults are discovered as they arise by continuously monitoring a number of important components of the electrical substation. To avoid an immediate breakdown, the energy provider can reroute the power through other components of the infrastructure. This gives the repair teams some time to plan the repairs and order the necessary parts.

According to Knag, this combined alarm system, which includes an online thermographic temperature alarm and perimeter protection intruder alarm, guarantees a high return on investment. “This system has a significant added value because it combines condition monitoring and security into one system. We anticipate that the thermographic component of the installation will result in a 20% reduction in breakdowns, which could result in annual savings of more than 8 million euros.

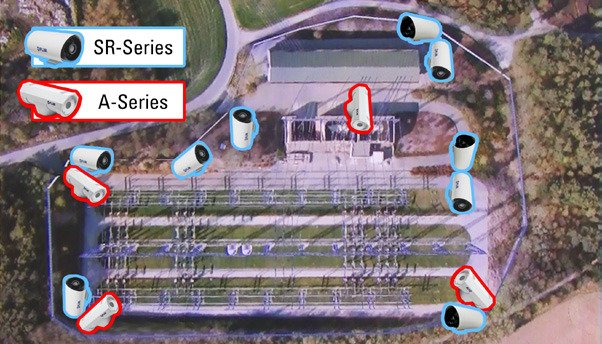

FLIR SR-Series thermal imaging cameras were used by Noralarm AS for the perimeter security system. According to Noralarm Sales Manager Mikke Sthl, “I have visited a number of other pilot projects with other intruder detection methods, such as sensor cables and visual light closed circuit television (CCTV) cameras, and in my experience, these technologies do not work.” These other technologies merely generate too many unnecessary alarms to work properly.

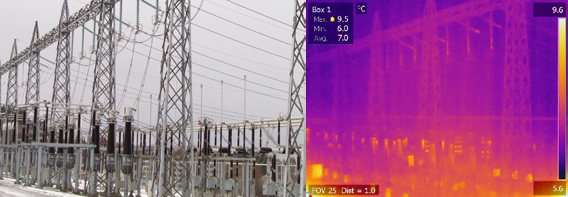

Noralarm looked into the use of thermal imaging cameras in order to reduce the number of unnecessary alarms at the Lyse Energy electrical substation to a more tolerable level. According to Ronny Hjrnevik, Installation Manager at Noralarm, “Thermal imaging cameras combine really well with video analytics software compared to regular CCTV cameras.” Since thermal imaging cameras create thermal imaging footage based on the infrared radiation given off by the scene, they offer high contrast thermal images under all circumstances. The thermal footage will clearly show intruders in the high contrast thermal images regardless of the weather or lighting conditions. As a result, the security system’s detection performance is much more consistent.

Hjrnevik continues, “This pairing of video analytics software with thermal imaging cameras also lowers the unwanted alarm rate.” “In most circumstances, the thermal contrast between a person and his surroundings is much greater than the color contrast. Therefore, a CCTV camera-based intruder detection system’s sensitivity must be very high in order for it to be accurate, but doing so results in a lot of unnecessary alarms. The sensitivity of the detection can be set much lower for a thermal imaging-based intruder detection system, leading to a much lower unwanted alarm rate because of the high contract between an intruder and his surroundings in the thermal image.

Sthl continues, “In actuality, the unwanted alarm rate at the Lyse Energy electrical substation is almost zero. “We conducted thorough tests, and in each test, the system successfully identified the intruders regardless of the weather or lighting. According to my experience, other technologies like sensor cables, CCTV video detection, and similar ones cannot achieve such a low rate of unwanted alarms without sacrificing intruder detection.

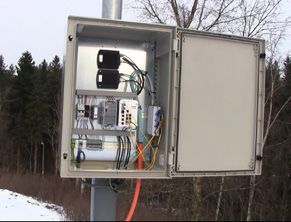

FLIR SR-Series thermal imaging cameras were used to secure the Lyse Energy electrical substation in Stavanger. These cameras have an uncooled Vanadium Oxide (VOx) microbolometer detector, which produces thermal images with a resolution of 320×480 pixels in the case of the Lyse Energy substation. FLIR also sells models with resolutions of 640×480 pixels or 160×120 pixels. FLIR also offers a wide range of optics to enable these cameras to flawlessly cover the entire perimeter. According to Hjrnevik, integrating cameras into a security network is not difficult. “We connected the FLIR SR-Series cameras’ analog video output to video encoders that digitize the footage. Following that, it is transmitted via Ethernet to a local server, which reviews the video and transmits it along with the alarm data to the main Noralarm control center in Stavanger.

The security system also includes thermography cameras for online condition monitoring in addition to thermal imaging security cameras. In order to increase the installation’s “value for money,” Noralarm allegedly added a thermographic temperature alarm system. “We are constantly looking for ways to improve our systems, so when we learned that the electric substation performs routine maintenance inspections with handheld thermal imaging cameras, we decided to incorporate online thermographic monitoring into our security system design.”

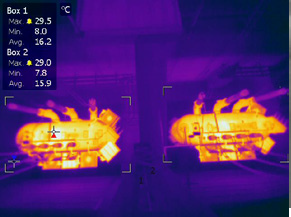

The system’s FLIR Fixed Condition Monitoring Smart Sensors, which are mounted in a waterproof housing, are the thermographic thermal imaging cameras used in it. The thermal images created by these radiometric thermal imaging cameras have a resolution of 320×240 pixels. The thermal image captures the smallest image details and temperature differences because each pixel is a non-contact temperature measurement with a thermal sensitivity better than 50 mK (0.05 °C). They can compare the temperatures in their images with user-defined settings and send that data to a central monitoring station for trend analysis and alarm functions thanks to the built-in logic, memory, and data communications. The thermography monitoring system for the Lyse Energy substation in Stavanger will automatically sound the alarm if certain regions of the thermal image exceed the previously set threshold temperature.

The critical components of the substation are continuously monitored by the four FLIR Fixed Condition Monitoring Smart Sensors that are included in the alarm system, according to Sthl. “An alarm will sound if any part of the monitored equipment exceeds the threshold temperature. The energy provider can then reroute the power to avoid breakdowns, and given that these breakdowns are expensive, I believe the thermographic system’s added value is one of the main reasons Lyse Energy selected our security system for this substation rather than one of our rivals.

The Lyse Energy substation now has the best all-around security system available thanks to Noralarm’s integration of FLIR thermal imaging security cameras with thermographic online condition monitoring. With the help of this security system, Lyse Energy can guarantee that its customers will always have access to energy, regardless of vandalism, terrorism, or component failures.

Copyright © 2025 Butler & Land Technologies, LLC. All Rights Reserved.

Web Design by Red Spot Design. Return & Refund Policy, Terms & Conditions