Solenoid Valve FAQ

Most frequent questions and answers about Solenoid Valves

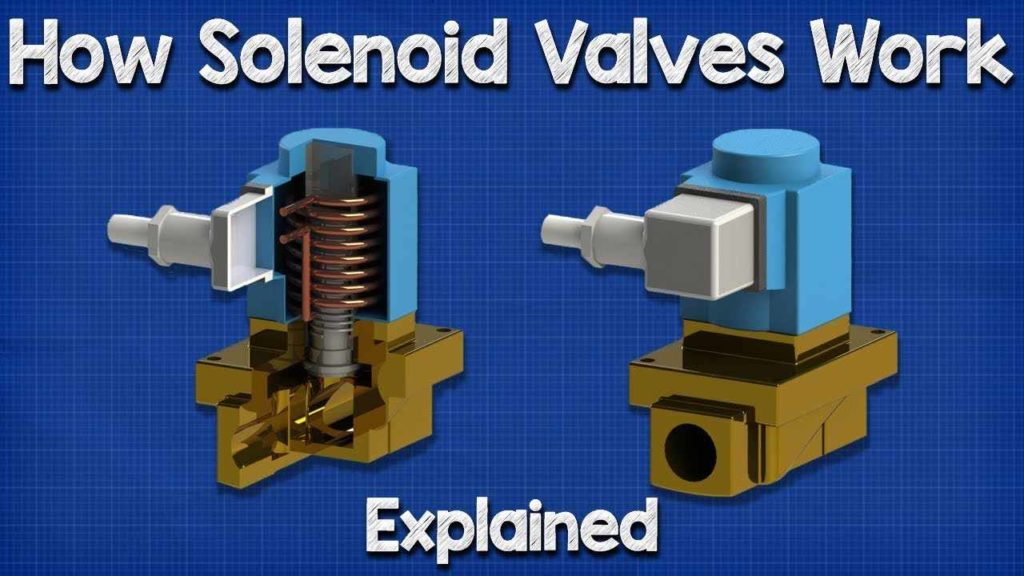

The definition of a solenoid valve is an electro-mechanical valve that is commonly employed to control the flow of liquid or gas. There are various solenoid valve types, but the main variants are either pilot operated or direct acting.

Solenoid valves are control units which, when electrically energized or de-energized, either shut off or allow fluid flow. The actuator takes the form of an electromagnet. When energized, a magnetic field builds up which pulls a plunger or pivoted armature against the action of a spring.

Solenoid valves are the most frequently used control elements in fluidics. They are commonly used to shut off, release, dose, distribute or mix fluids. For that reason, they are found in many application areas.

Common uses. Solenoid valves are used in fluid power pneumatic and hydraulic systems, to control cylinders, fluid power motors or larger industrial valves. Automatic irrigation sprinkler systems also use solenoid valves with an automatic controller.

A solenoid valve is an electrically controlled valve. The valve features a solenoid, which is an electric coil with a movable ferromagnetic core (plunger) in its center. In the rest position, the plunger closes off a small orifice. An electric current through the coil creates a magnetic field.

Most solenoids unscrew counter-clockwise to remove. If the plunger doesn’t move easily and smoothly, replace the solenoid; it is damaged and can’t be repaired. Do not apply any oil or lubricant to the solenoid plunger, if it is sticking it is not repairable, replace it.

The quickest way to test the solenoid valve is to apply a charge directly to it. There are two wires which cross directly above the valve as it lays in the timer that you will touch with a multimeter. This should send a charge onto the valve, and if it is functioning normally, it will open.