FREE No Obligation Quote

Our Balluff Sensors

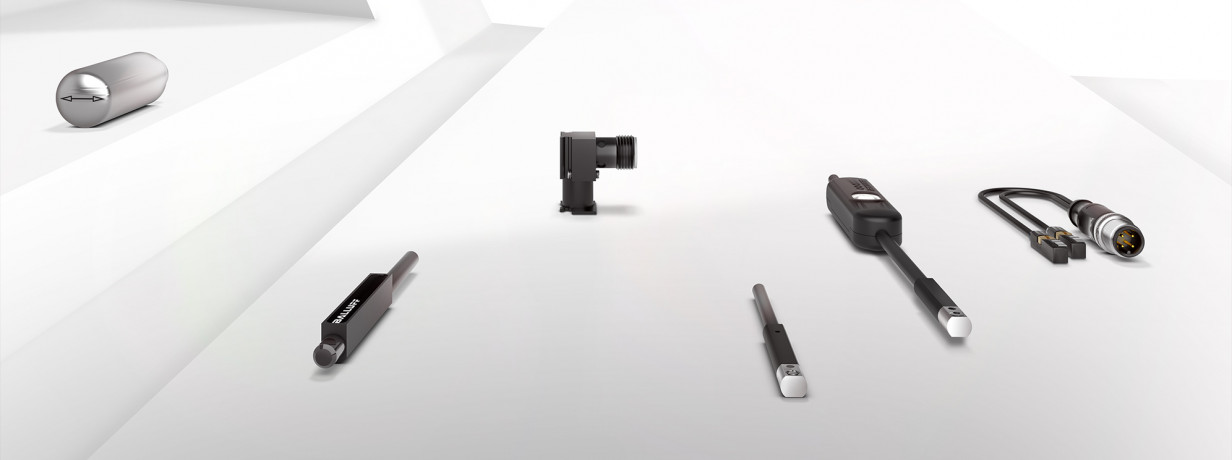

Inductive Sensors

Balluff offers a wide range of inductive sensors with diverse designs for nearly any application: from standard sensors to sensors with increased switching distance, hygienic sensors, high-pressure sensors, ex-zone sensors for hazardous areas, and factor 1 sensors. Some sensors have an additional ceramic or PTFE coating so that weld spatter, for example, cannot adhere to them. Sensors that are both factor 1 and all-metal are also available.

Capacitive Sensors

Capacitive sensors detect objects and the fill level of all non-conducting materials, liquids, pellets, and powders directly or through a container wall. The patented Smart Level technology of the sensors compensates for moisture, foam and adhesion of all sorts – even through glass and plastic walls up to 10 mm thick. This makes the sensors ideal as fill level sensors for conductive media. And guarantee you high application security.

Photoelectric Sensors

Photoelectric sensors check presence, shape, colour, distance, and thickness – optimized for robotics, automation, assembly, and handling. They are real experts with various strengths: detecting and counting parts, monitoring stack heights, through-glass detection, aligning small parts, detecting marks, fill level detection, and much more! The wide Balluff spectrum offers every light type, whether red light, infrared or laser technology, in different ranges. With and without background suppression.

Magnetic Field Sensors

Magnetic field sensors are used chiefly on cylinders and grippers for monitoring the piston position. The sensor thus recognizes the field of the magnet integrated into the piston through the actuator wall. With their contactless position detection, Balluff’s magnetic field sensors function reliably and wear free: No contact erosion, no bounce and only clean contact points. Even at high movement speeds, the piston position is reliably recognized.

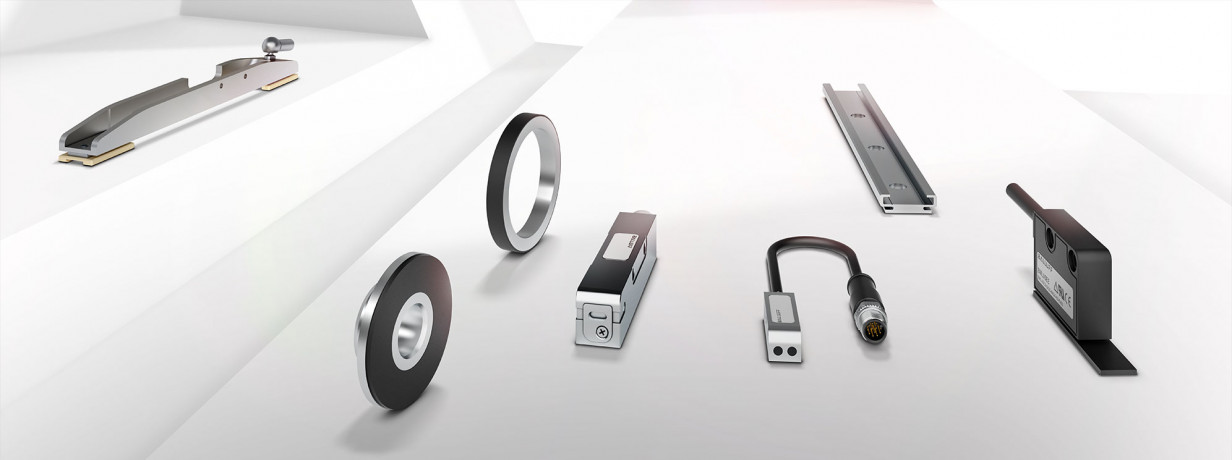

Mechanical Cam Switches

Position and row-position counters are classics in the metal-working industry and world-wide automotive production. They have proven their worth in automation for decades. Mechanical sensors are used for positioning and limit switch tasks on machine tools and presses, flexible production centres, robots, assembly and conveying equipment, and in machine and plant construction. For decades, they have proven their worth as the traditional strongmen of automation.

Ultrasonic Sensors

Whether your application is position detection, distance measurement, or the detection of solid, powder, or liquid media: BUS ultrasonic sensors are precise all-rounders. They measure fill levels, heights and sag without making contact as well as count and monitor the presence of objects. Regardless of the colour, transparency, and surface texture, they always perform really well. Fog, dust and impurities are also not a problem for them.

Magnetic Encoders

Balluff’s magnetically encoded sensors are designed for precise positioning and velocity sensing in highly dynamic applications. The high-precision, fast-acting measuring systems are optionally equipped with magnetically encoded linear or rotative measuring bodies. They are suitable for both linear and rotary applications, for incremental or absolute position measurement.

Magnetostrictive Sensors

Magnetostrictive position measurement systems come into use generally where high reliability and precision are demanded in position and speed measurement. Over long distances, our contact-free and absolute measuring systems are suitable for all industry-standard interfaces and for a wide range of applications. Even under extreme surrounding conditions, they guarantee a high machine and system availability.

Inclination Sensors

Accurate position control and the continuous tracking and monitoring of rotational movements are the number one concern in many applications. Our BSI inclination sensors measure the deviation to a horizontal or vertical axis up to 360°. With two different measurement principles and different angular ranges, the inclination sensors from Balluff are appropriate for many industries and applications.

Pressure Sensors

BSP pressure sensors monitor pressures of gaseous and fluid media; they can also be used in a variety of ways in factory automation. Available with stainless steel housings are designed for the demanding requirements of extended temperature ranges and harsh environments. With your rotational housing and the simple, VDMA-compliant programming, they can be flexibly mounted as well as conveniently serviced.

Temperature Sensors

With our sensors you can monitor media temperatures in a wide range of applications. When used directly in liquid and gaseous media, our temperature sensors provide reliable support.

Flow Sensors

Flow sensors let you measure and monitor the flow of process media, like lubricant or cooling water, in a wide range of applications. When you are alerted that the flow has slowed or stopped, you can respond quickly and prevent an unplanned machine downtime or even system stop. This is how flow sensors, like pressure or temperature sensors, contribute to process security.

Condition Monitoring Sensors

Unscheduled stops and faults in the production process can be avoided using the BCM multi-functional condition monitoring sensors. These intelligent sensors provide condition information which you can use to automate manual inspections. This condition data is also an important component of IIoT for implementing smart and flexible manufacturing.

Digital Position Indicators

The digital position indicator from Balluff sets new standards in the area of intuitive and clear operator guidance. The digital indicator is washdown-capable and has a variety of internal sensors with extended IO-Link functionality. There are therefore virtually no limits to the range of applications for the digital indicator: from classic machine tools and automation technology to heavy-duty use in the food & beverage sector.

Rotary Encoders

Balluff’s encoders are used wherever mechanical values for angles of rotation need to be captured. The detected movement is converted into electrical signals to help you to position all critical machine parts with high precision. The robustness of the rotary encoders enables use even under extreme conditions, such as in the field of food processing and packaging, mobile working machines as well as in mechanical engineering.